``The must have tool for 2025, A Fabricators Dream``

TUBE LASER SPECS

24 Machine Sizes

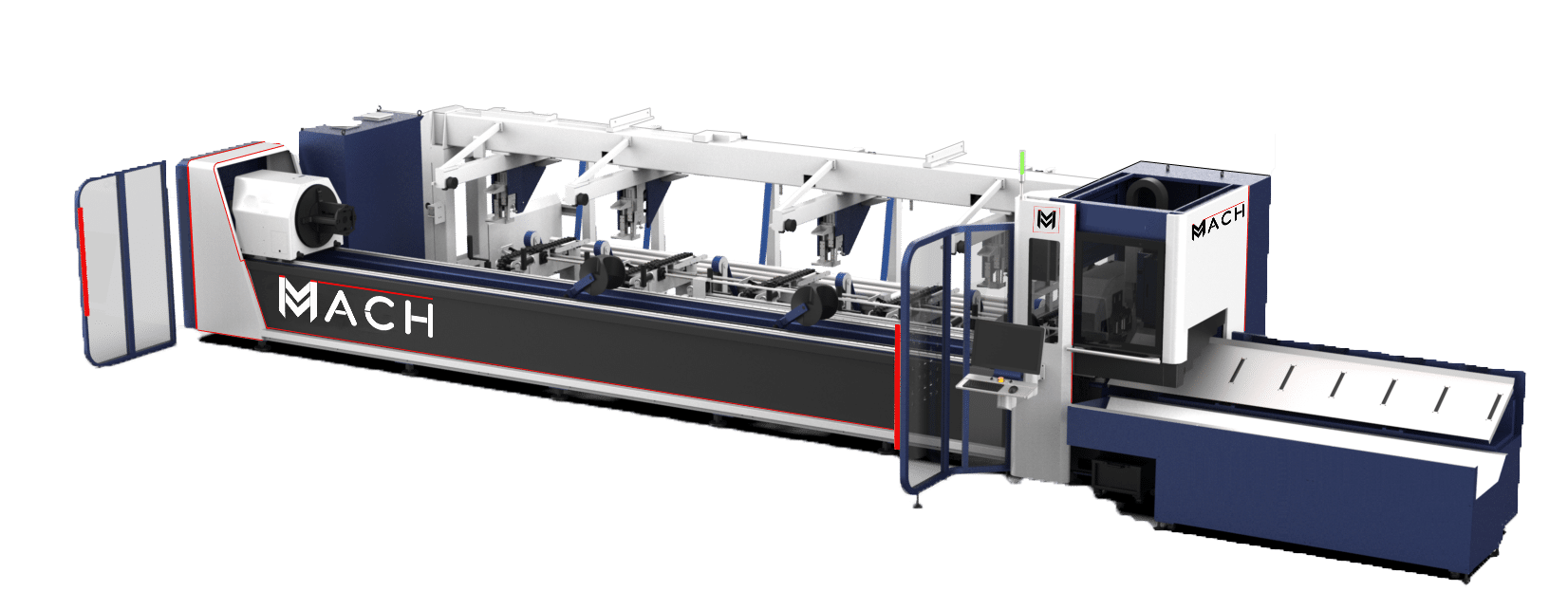

2D and 3D Cutting

European Design

Offline Software

Touch Screen Controls

TUBE LASER BENEFITS

Precision

Accuracy

Loading/Unloading

User Friendly Controls

Reduced Material Waste

Partner with MACH?

Innovation

Reliability

Specific Industry Knowledge

Customer Satisfaction

Rigorous Testing & Training

Benefits of Using CNC Tube Lasers

CNC tube lasers are a game-changer in manufacturing with their speed, precision and versatility which cannot be matched by conventional methods. The essential tool for innovative production will be the benefits you can find below.

Unmatched Precision. CNC tube lasers are really precise so can cut very incredible and detailed designs. Whether you need a precise cut or a perfect bevel, these machines deliver consistency and perfection on the demanding job.

Enhanced Efficiency. CNC tube lasers save time by automating cutting, drilling, and shaping into one process instead of three. By diminishing the need for manual intervention, errors are also minimized, as such, productivity is greatly enhanced and costs are also reduced. Material Versatility. CNC tube lasers are engineered for many materials which can smooth cut metals such as steel, aluminum and titanium.

Also, lighter alloys can smoothly cut. Various industries utilize tube cutting systems that can cut round, square, rectangular, and special profiles tubes. Optimized Material Usage. Cutting with precision wastes less.

Manufacturers can lower their costs with the help of CNC tube lasers and save the environment. Flexibility in Design. CNC tube lasers allow manufacturers to product prototypes and high-volume production runs, enabling them to produce lightweight, strong, and attractive components based on their needs.

Using CNC tube laser technology will help manufacturers get better quality, quicker turnaround time and lower operational cost over competition.

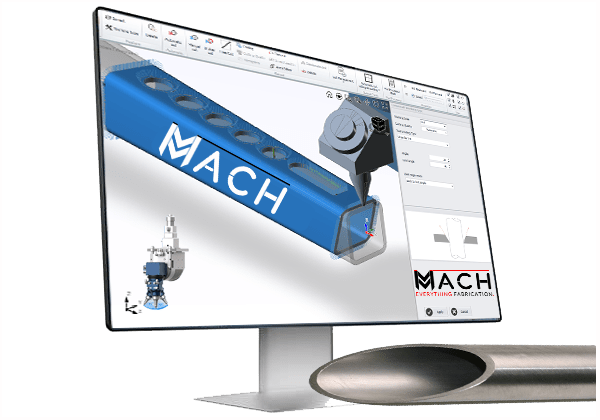

Unrivaled Tube Software Solutions

MACHTubes is the ideal software solution for manufacturing light and thin-walled tubes using laser machines, whether you need straight or beveled cuts.

This powerful software generates precise CNC programming to ensure seamless production of tube components. It’s compatible with both dedicated tube-cutting machines (handling round, square, rectangular, and open profiles) and hybrid machines capable of processing both tubes and sheet metal.

Key Software Features of CNC Tube Lasers

- Optimized Nesting: Reduces material waste with efficient part arrangement.

- 3D Simulation: Visualize and simulate cutting for error-free production.

- Custom Profile Support: Handles round, square, and complex shapes easily.

- Error Detection: Automatically identifies design and cutting issues.

- CAD/CAM Integration: Imports designs seamlessly for streamlined workflows.

- Real-Time Monitoring: Tracks and adjusts cutting processes on the go.

Flexibility, Precision, and Efficiency for Your Manufacturing

Tube laser cutting machines deliver unmatched precision and efficiency, setting them apart from traditional cutting methods. Their advanced capabilities make them a go-to choice across various industries, including food processing and agriculture. These machines easily handle materials with large wall thicknesses and diameters, making them an ideal solution for modern manufacturing needs.

With cutting-edge laser technology, manufacturers are embracing this advanced method for its exceptional performance and accuracy. By integrating laser cutting into production, businesses can achieve higher part precision and streamline their processes, staying ahead in today’s competitive market.

Recent Installations

At MACH, we take pride in delivering state-of-the-art CNC tube laser solutions tailored to our customers’ needs. Our recent installations showcase the versatility and precision of our machines across a variety of industries, including automotive, construction, and bespoke manufacturing. Each project reflects our commitment to excellence, from initial setup and operator training to ensuring seamless integration into production lines. Explore how our advanced technology is transforming businesses and setting new standards in efficiency and quality

Advantages of Designing with CNC Tube Lasers

CNC tube laser technology opens up a world of possibilities for modern design and manufacturing. With its ability to produce intricate cuts and complex geometries with unmatched precision, it offers designers unparalleled creative freedom. Whether working with round, square, rectangular, or custom profiles, CNC tube lasers enable seamless execution of even the most intricate designs, ensuring high-quality results every time.

One of the standout advantages is efficiency. CNC tube lasers significantly reduce production time by combining cutting, drilling, and shaping into a single automated process. This not only speeds up manufacturing but also eliminates the need for multiple tools and setups, minimizing errors and maximizing consistency.

Parts Like Never Before

Designers and engineers can also capitalize on material optimization. With its ability to cut with extreme accuracy, CNC tube lasers reduce waste, saving both resources and costs. Additionally, these machines are compatible with a wide range of materials, from light metals to thicker-walled tubes, making them suitable for diverse applications.

Ultimately, designing with CNC tube lasers empowers manufacturers to create lightweight, durable, and aesthetically superior components, setting new standards in industries such as automotive, aerospace, furniture, and construction. It’s a perfect blend of innovation and practicality.

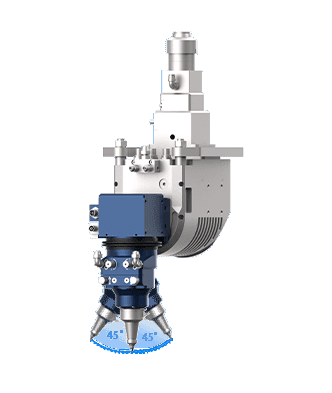

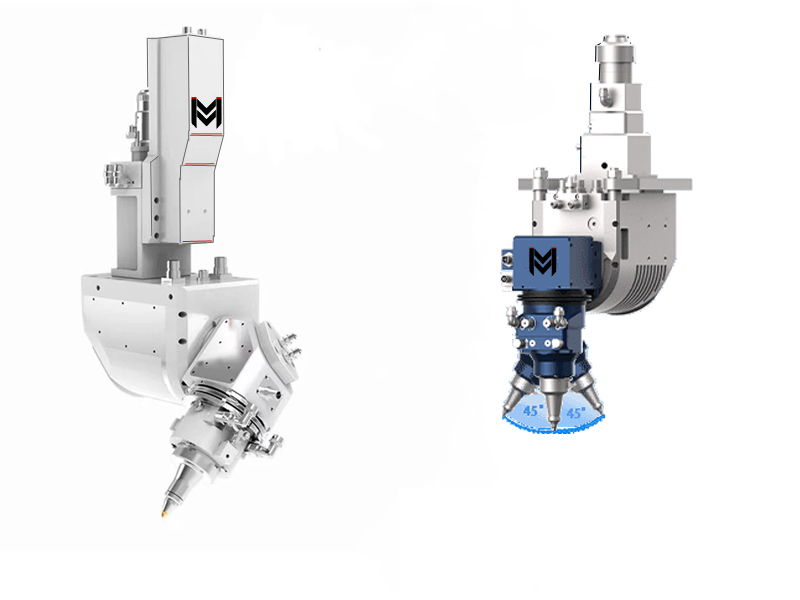

Advanced Bevel Cutting Heads

MACH’s advanced bevel cutting heads bring unmatched versatility and precision to your CNC fiber laser operations. Designed for complex 3D cutting, these heads allow for precise bevel cuts at various angles, making them perfect for applications like welding preparation and structural steel fabrication. Featuring dynamic angle adjustment and high-speed rotation, they deliver consistent, clean cuts even on thick materials. Our bevel cutting heads are compatible with leading laser systems, ensuring seamless integration and reliable performance. With MACH, you can achieve superior edge quality and expand your cutting capabilities, taking on more advanced projects with confidence.

Automated Loading and Unloading Systems

MACH’s Automated Loading and Unloading Systems are designed to streamline your production process and maximize efficiency. These systems enable seamless material handling, reducing downtime and boosting throughput. Whether working with thin sheets or heavy plates, our solutions ensure fast and precise loading and unloading, minimizing manual intervention and improving workplace safety. Fully compatible with MACH’s CNC fiber lasers, these systems include options like automated storage racks, pallet changers, and robotic arms. Ideal for high-volume operations, they optimize workflow, save valuable time, and help you maintain consistent productivity levels, even during peak demand periods.

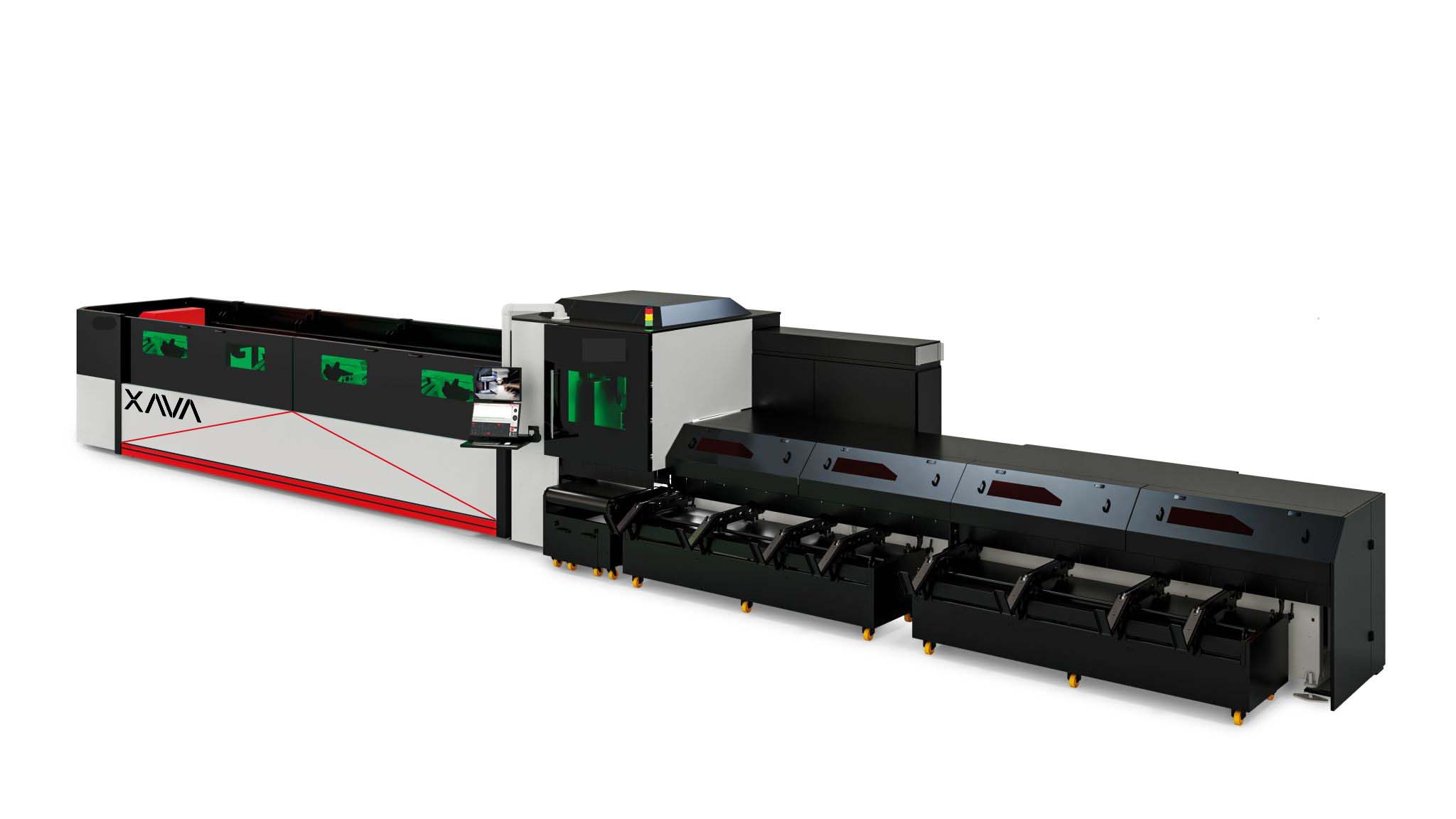

Evo-A9m-3kW CNC Tube Laser

The Evo-A9m-3kW is a cutting-edge CNC tube laser designed to meet the demands of modern manufacturing. Powered by a robust 3kW laser, it delivers exceptional precision and speed, effortlessly handling a wide range of materials and profiles, including round, square, and rectangular tubes. With advanced features like automatic loading and unloading, intelligent nesting software, and seamless CAD/CAM integration, the Evo-A9m optimizes productivity and reduces waste. Its versatile design is ideal for industries such as automotive, construction, and custom fabrication, making it the perfect solution for businesses seeking efficiency, reliability, and superior cutting quality.

Design & Cut Complex Parts With Ease

CNC tube lasers are engineered to handle even the most intricate designs with precision and efficiency. From complex geometries to detailed patterns, these machines simplify the process, allowing you to bring creative ideas to life without compromising on accuracy. Whether it’s angled cuts, beveled edges, or custom profiles, our advanced technology ensures flawless execution every time. With CNC tube lasers, designing and cutting complex parts has never been easier.

Industry Leaders in Supplying Metal Fabrication Machinery

Why Choose MACH?

Industry Leaders

Tailored Solutions

Commitment To Quality & Performance

Trusted By Industry Professionals

Innovative Machinery

Leading Brands and Technologies

Innovative Solutions for Every Need

Proven Track Record of Excellence

Experience/Knowledge

Expertise and Experience

Customer-Centric Approach

Comprehensive Support and Service

Full Tech Support

Proven Track Record

Accessible

Reliable

Innovative Cutting Solutions with Our CNC Fibern Tube Laser Range | MACH

Revolutionizing Manufacturing with Our CNC Tube Laser Machines

CNC Tube Laser Solutions | Precision and Versatility Redefined

At MACH, we bring you state-of-the-art CNC tube laser machines designed to push the boundaries of precision, efficiency, and innovation. Perfect for a wide range of industries, from construction to custom manufacturing, our tube lasers offer unparalleled flexibility for cutting complex geometries and profiles with ease.

Why Choose MACH CNC Tube Lasers?

- Exceptional Cutting Accuracy

Achieve flawless results with advanced laser precision, capable of handling intricate cuts on round, square, and rectangular tubes, as well as open profiles. - Efficient Production

Our tube lasers streamline processes by combining cutting, drilling, and shaping in a single operation, significantly reducing production times and costs. - Versatile Material Handling

From thin-walled tubes to thick materials, MACH CNC tube lasers work seamlessly with a variety of metals, including stainless steel, aluminum, and carbon steel. - Innovative Software Integration

Advanced CAD/CAM integration and intelligent nesting algorithms ensure efficient material usage, reducing waste and boosting productivity.

Key Features of MACH CNC Tube Lasers

- Powerful Laser Technology: Available in configurations up to 3kW for precise, high-speed cutting.

- Automated Material Loading: Increases efficiency and reduces manual handling.

- Flexible Profile Support: Cuts round, square, rectangular, and custom profiles effortlessly.

- User-Friendly Interfaces: Intuitive controls with 3D visualization for error-free operation.

- Robust Safety Features: Enclosed designs and fume extraction systems for a secure workspace.

Applications

MACH CNC tube laser machines are ideal for:

- Structural frameworks

- Custom furniture manufacturing

- Automotive and aerospace components

- Industrial piping and tubing

MACH Support and Service

When you invest in MACH, you’re partnering with a team dedicated to your success:

- Comprehensive Training: Empower your team to maximize machine performance.

- Preventative Maintenance: Ensure your machine stays in peak condition.

- 24/7 Technical Support: Expert assistance whenever you need it.

Transform your production capabilities with MACH’s CNC tube laser solutions. Experience precision, efficiency, and innovation like never before. Contact us today to learn more!