What Is Laser Welding

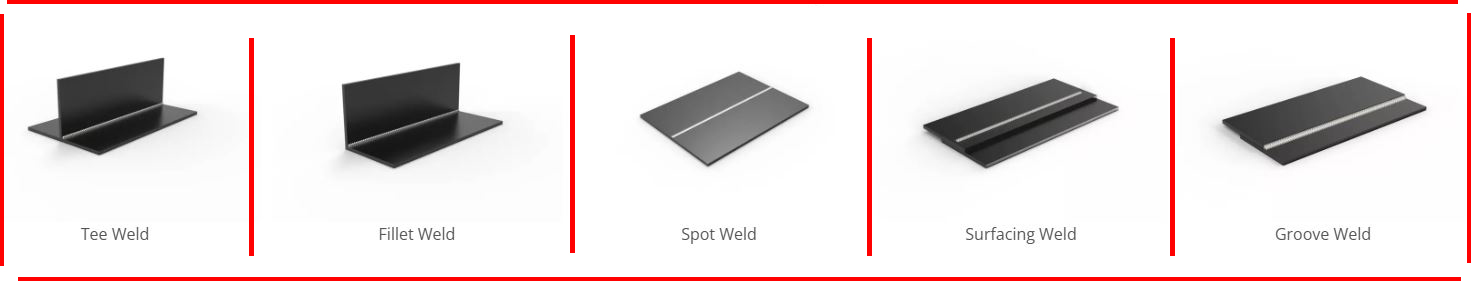

Laser welding is an advanced technique that uses a concentrated laser beam to heat, melt, and fuse two materials together. This process involves the use of cutting gas to prevent unwanted reactions, such as oxidation, that could compromise the quality of the welded joint. By focusing high-intensity laser energy on the weld area, the materials are rapidly heated to their melting point, creating a precise and strong bond.

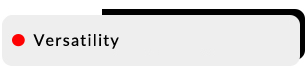

One of the key advantages of laser welding is its ability to work with a wide range of materials, from simple metals to complex alloys, regardless of their thickness or intricacy. The technology is highly versatile, making it suitable for industries that require precision and flexibility, including automotive, aerospace, electronics, and medical device manufacturing.

In addition to its versatility, laser welding produces minimal heat during the process, which helps reduce the risk of material distortion. The localized heating ensures that only the area around the weld is affected, preserving the integrity of the surrounding material. This low-heat input also results in a smaller heat-affected zone (HAZ), leading to less warping, fewer cracks, and better overall weld quality.

Laser welding is renowned for its accuracy and fine detailing capabilities. The precision of the laser allows for smaller, more intricate welds with minimal margin for error. This makes it ideal for applications that require high standards of quality and tight tolerances.

Overall, laser welding offers a combination of speed, efficiency, and high-quality results, making it an invaluable solution for modern manufacturing needs. Whether you’re welding delicate components or handling large-scale industrial projects, laser welding delivers unmatched performance and precision.

INDUSTRIAL WELDING SYSTEMS | LASER WELDING

Laser Welding Systems | Precision Metal Welding Solutions

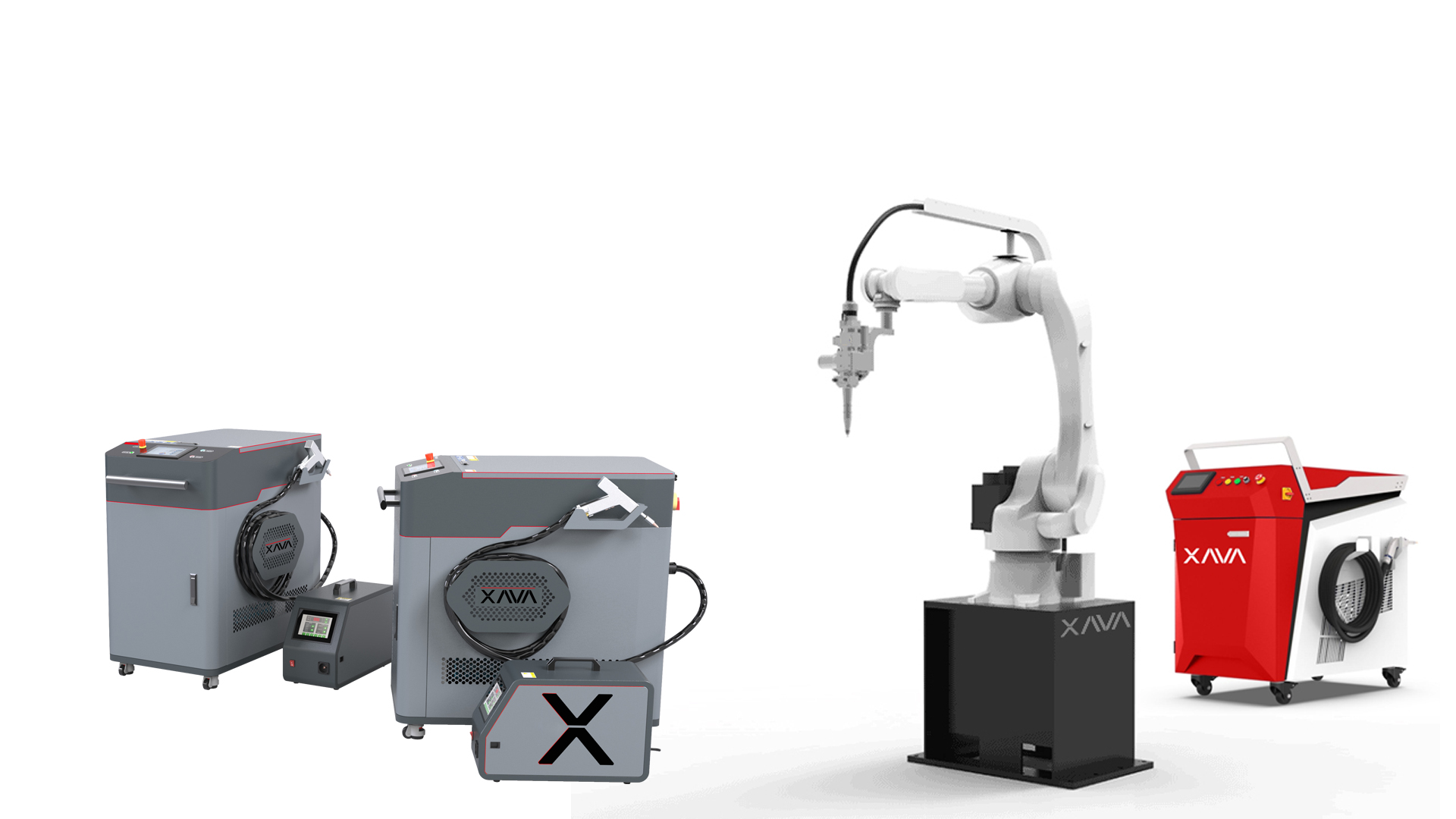

At MACH, we specialize in high-quality laser welding systems designed for precision and efficiency. Whether you need a compact, entry-level solution or a powerful, industrial-grade laser welding system for large-scale production, we have the perfect option for your needs. Our laser welding machines deliver exceptional precision, ensuring smooth, strong welds for even the most intricate and demanding projects. With advanced features like high-speed operation and minimal heat-affected zones, our systems provide unmatched quality and productivity. Designed to work with a wide range of metals, including stainless steel, aluminum, and titanium, MACH’s laser welders offer unparalleled versatility. Our machines are engineered for easy integration into your existing workflow, maximizing uptime and minimizing operating costs. With a focus on durability, low maintenance, and superior performance, our laser welding solutions are built to last. Whatever your welding requirements, MACH offers reliable, cost-effective laser welding solutions to help you achieve superior results every time.

SPECIFICATIONS

Maintenance & Durabilit

Versatility Across Materials

European Design

Offline Software

Touch Screen Controls

Partner with MACH?

Knowledge & Innovation

Reliability

Specific Industry Knowledge

Technical Know How

Customer Satisfaction

PLASMA ADVANTAGES

Precision

Accuracy

Support

User Friendly Controls

Reduced Material Waste

LASER OR TRADITIONAL WELDING?

THE ANSWER IS CLEAR WITH XAVA.

Laser welding offers a revolutionary approach to metal joining that far surpasses traditional methods like TIG and MIG welding. With XAVA’s laser welding technology, you can achieve welding speeds up to 10 times faster, boosting productivity and enhancing profitability.

The precision of laser welding ensures high-quality welds with minimal heat-affected zones and reduced porosity, resulting in superior weld integrity. In addition, XAVA’s laser welding systems are user-friendly, making them accessible to both experienced welders and newcomers, streamlining training and operation.

Laser welding is the future of the industry, providing efficiency, exceptional quality, and cost-effectiveness for modern manufacturing needs.

BENEFITS | LASER WELDING

Low Heat Input for Minimal Part Distortion or Deformation:

Laser welding systems offer a key advantage in terms of low heat input, meaning less thermal impact on the material during the welding process. This results in significantly reduced distortion or deformation of the welded parts, especially when dealing with thin or heat-sensitive materials. The localized heating of the laser beam ensures that only the weld area is affected, leaving the rest of the material unaffected. This is particularly crucial for high-precision applications, where even slight changes in the material’s shape can compromise the quality of the final product.

ADVANTAGES OF OUR TECH

Built-In Factory Presets for All Materials and Thicknesses:

One of the standout features of MACH’s laser welding systems is their built-in factory presets for a wide range of materials and thicknesses. These presets take the guesswork out of the setup process by providing optimized settings for common materials such as stainless steel, aluminum, and titanium. Whether you’re welding thin sheet metal or thick plates, the system adjusts parameters like power, speed, and focus automatically, ensuring optimal results each time. This not only improves consistency but also reduces the likelihood of errors, making the machine highly efficient for operators of all skill levels.

High-Speed Welding Across a Wide Range of Materials and Thicknesses:

MACH’s laser welders are designed for high-speed performance, making them ideal for both high-volume production and intricate, detailed work. The system’s high energy density allows it to weld through a variety of materials, including those that are typically difficult to handle, such as thick steels or non-ferrous metals. With a faster welding process and shorter cycle times, businesses can significantly increase their productivity while maintaining weld integrity and quality. The ability to weld across a broad range of materials and thicknesses without sacrificing speed or precision gives manufacturers the flexibility to take on diverse projects and meet demanding production schedules.

A GAME CHANGER

Industry Leaders in Supplying Metal Fabrication Machinery

Why Choose MACH?

Industry Leaders

Tailored Solutions

Commitment To Quality & Performance

Trusted By Industry Professionals

Innovative Machinery

Leading Brands and Technologies

Innovative Solutions for Every Need

Proven Track Record of Excellence

Experience/Knowledge

Expertise and Experience

Customer-Centric Approach

Comprehensive Support and Service

Full Tech Support

Proven Track Record

Accessible

Reliable

Industrial Welding Solutions From Our Range of FIBER LASER WELDERS

What You Need to Know Before Investing in a Laser Welding System

Before purchasing a laser welding system, it’s important to consider several factors to ensure you choose the right machine for your needs. Here’s what you should know:

- Welding Material and Application The type of material you plan to weld will affect the choice of your laser welding machine. MACH’s systems are designed to handle a wide range of materials, including stainless steel, aluminum, and titanium, delivering exceptional results for both thin and thick materials. Consider the types of metals you work with and the precision required for your specific applications.

- Laser Power and Beam Quality Laser power determines the intensity of your welding, while beam quality impacts the precision of your welds. MACH offers laser welders with a variety of power settings, ensuring you get the right balance of speed, precision, and penetration for your projects. Higher power is ideal for thicker materials, while lower power delivers fine, detailed welds for smaller, more delicate jobs.

- Controller and Software The controller and software are crucial for ease of use and operational efficiency. MACH’s laser welding machines are equipped with intuitive, user-friendly software that allows quick programming, precise adjustments, and real-time monitoring. This ensures consistent welds, maximum efficiency, and reduced human error during production.

- Training and Application Knowledge At MACH, we don’t just sell equipment—we provide in-depth training to ensure you maximize the potential of your laser welding system. Our team offers hands-on training tailored to your specific applications, empowering your operators with the knowledge and skills to produce consistent, high-quality welds every time. We understand the unique demands of various industries and provide the application expertise to support your business needs.

- Local Support and Maintenance A key factor in maintaining the performance of your laser welding system is ongoing support and maintenance. MACH offers comprehensive local service, including installation, preventive maintenance, and troubleshooting. Our experienced technicians are ready to assist you with any issues, ensuring minimal downtime and long-term, reliable performance.

- Spare Parts and Backup MACH ensures that all our customers have access to a full range of genuine spare parts and backup support. We stock high-quality components to keep your laser welding system running smoothly. Our service team is always available to help with parts replacement and to provide troubleshooting assistance, giving you peace of mind that your investment is protected.