``CNC Fiber Laser | Fast, flexible, and precise: Smart machinery for laser cutting``

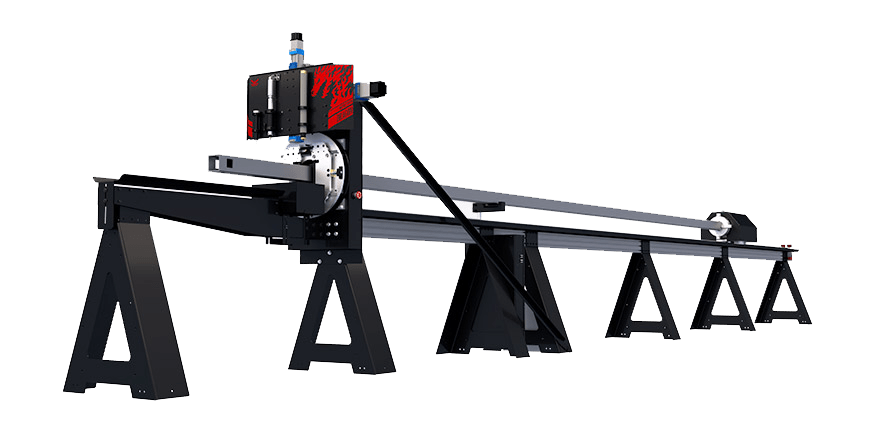

CNC Tube Plasma Spec

4 Profiles

Engrave

Mark/Cut

Add Bend Marks

Import Iges/Stp

SYSTEM ADVANTAGES

Precision

Affordable

Hypertherm Technology

Support Online

Easy To Use

Partner with MACH?

Tube Specialists

Machine Know How

Specific Industry Knowledge

Technical Expertise

Onsite Training

Precision and Speed | Hypertherm Tube Plasma

- Why Choose Hypertherm Plasma?

- Industry-Leading Technology: Trusted by professionals worldwide.

- Clean, Accurate Cuts: Reduced waste and minimal edge preparation.

- High Productivity: Faster throughput without sacrificing quality.

- Low Operating Costs:

- Energy-efficient systems with long-lasting consumables.

Precision and Speed | Hypertherm Tube Plasma

- Why Choose Hypertherm Plasma?

- Industry-Leading Technology: Trusted by professionals worldwide.

- Clean, Accurate Cuts: Reduced waste and minimal edge preparation.

- High Productivity: Faster throughput without sacrificing quality.

- Low Operating Costs:

- Energy-efficient systems with long-lasting consumables.

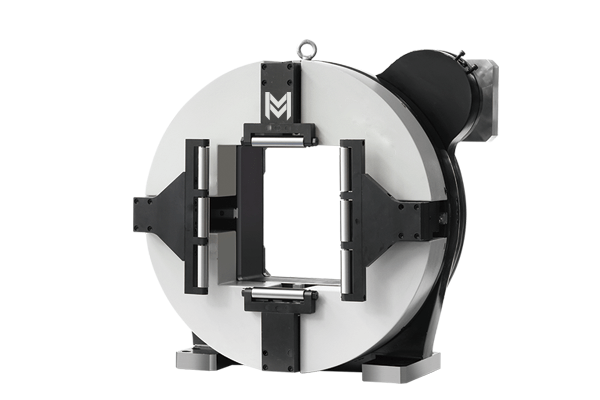

Tube Plasma Cutting Size Capacity

The roller gate design gives the versatility of handling both round pipe and square or rectangular tube (RHS & SHS).

- Round: 13 – 152mm diameter.

- Rectangle & Square: 13 – 100mm x 13 – 100mm.

- Chuck pass through (for processing tube lengths longer than the machine): Round Pipe max 50mm,

Square Tube max 35 x 35mm. - Machine Travel Length: Max 7,400mm of travel in one position / unlimited when re-positioned.

Advanced Bevel Cutting Heads

MACH’s advanced bevel cutting heads bring unmatched versatility and precision to your CNC fiber laser operations. Designed for complex 3D cutting, these heads allow for precise bevel cuts at various angles, making them perfect for applications like welding preparation and structural steel fabrication. Featuring dynamic angle adjustment and high-speed rotation, they deliver consistent, clean cuts even on thick materials. Our bevel cutting heads are compatible with leading laser systems, ensuring seamless integration and reliable performance. With MACH, you can achieve superior edge quality and expand your cutting capabilities, taking on more advanced projects with confidence.

The Dragon’s engraver unit is second to none.

- Standard feature on every Dragon machine.

- An inline oiler keeps the engraver functioning efficiently.

- Used for part identification marking and for designs that are to be etched onto the material.

Mark, Label or Etch with Accuracy = Assemble with ease

More than just a plasma cutter: Thanks to it’s marking capability, the Dragon A400 will bring you massive

time and cost gains when it comes to assembling your parts.

- Precisely mark and label tubes with: locations, bend order, rotations, angles, saddle marks (where tubes

will intersect for quick and accurate assembling) & much more. - Marks with permanent marker or engraver.

Advanced Solutions for Structural Steel: Larger Tube Plasma Machines

When it comes to handling heavy-duty cutting tasks for H Beams, I Beams, and other structural steel components, precision and power are paramount. Our larger CNC tube plasma machines are engineered specifically for these demanding applications, combining robust construction with advanced technology to deliver exceptional results.

Designed for Structural Steel Applications

Structural steel requires a specialized approach due to its size, weight, and critical role in construction and industrial projects. Our larger machines are equipped to:

- Cut H Beams, I Beams, Channel, and Angle steel with precision.

- Handle thicker materials and longer profiles with ease.

- Perform complex cuts such as notches, slots, and bevels, ensuring perfect fit-ups for welding and assembly.

Precision Cutting for Every Job

These machines utilize Hypertherm plasma systems to deliver:

- Clean, accurate cuts with minimal distortion, even on large and heavy materials.

- Consistent performance, enabling high-quality production for bridges, buildings, industrial equipment, and more.

Heavy-Duty Performance Meets Efficiency

Our structural plasma cutting machines are built to withstand the rigors of large-scale fabrication:

- Reinforced frames and tables designed for oversized and heavy profiles.

- Powerful drives and motion systems that ensure smooth operation, even with the largest materials.

- Advanced software integration, allowing for optimized nesting and precise part positioning.

Why Choose Our Machines for Structural Steel?

- Versatility: Capable of processing a wide range of structural profiles.

- Speed and Efficiency: Reduce production time with high-speed cutting and automated processes.

- Scalability: Ideal for both small workshops and large-scale fabricators.

- Hypertherm Integration: Industry-leading plasma technology ensures reliable, high-quality cuts.

Applications

- Structural fabrication for construction and infrastructure projects.

- Precision components for industrial machinery.

- Custom profiles for oil, gas, and energy sectors.

Automated Loading and Unloading Systems

MACH’s Automated Loading and Unloading Systems are designed to streamline your production process and maximize efficiency. These systems enable seamless material handling, reducing downtime and boosting throughput. Whether working with thin sheets or heavy plates, our solutions ensure fast and precise loading and unloading, minimizing manual intervention and improving workplace safety. Fully compatible with MACH’s CNC fiber lasers, these systems include options like automated storage racks, pallet changers, and robotic arms. Ideal for high-volume operations, they optimize workflow, save valuable time, and help you maintain consistent productivity levels, even during peak demand periods.

Design & Cut Complex Parts With Ease

CNC fiber lasers give you the ability to design and cut complex parts with unparalleled precision and efficiency. Thanks to advanced software integration and high-accuracy cutting heads, intricate geometries, tight tolerances, and detailed designs are easily achievable. Whether you’re working on custom components, prototypes, or highly specialized industrial parts, MACH’s fiber lasers handle even the most complicated cuts effortlessly. This capability not only reduces the need for secondary operations but also expands your production possibilities, allowing you to take on more demanding projects and deliver exceptional results every time.

Industry Leaders in Supplying Metal Fabrication Machinery

Why Choose MACH?

Industry Leaders

Tailored Solutions

Commitment To Quality & Performance

Trusted By Industry Professionals

Innovative Machinery

Leading Brands and Technologies

Innovative Solutions for Every Need

Proven Track Record of Excellence

Experience/Knowledge

Expertise and Experience

Customer-Centric Approach

Comprehensive Support and Service

Full Tech Support

Proven Track Record

Accessible

Reliable

Impressive Cutting Solutions From Our Range of CNC Fiber Plasma | Machines

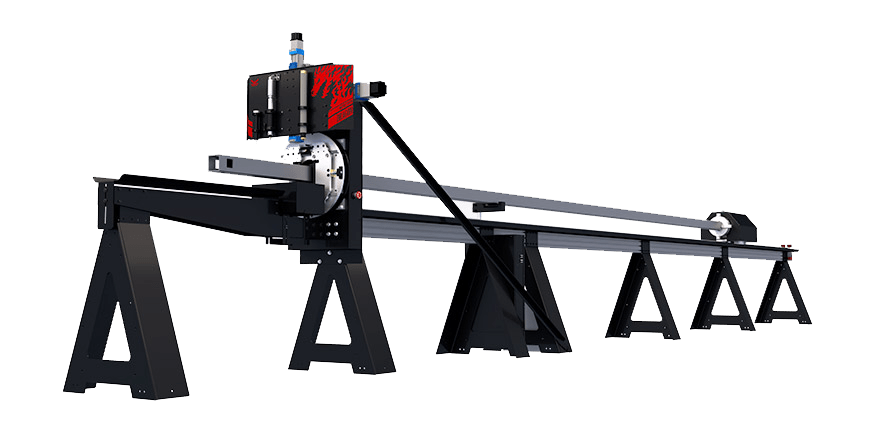

Impressive Cutting Solutions for Heavy Fabrications – MACH CNC Tube Plasma Machines

CNC Tube Plasma Solutions | Power and Precision for Heavy Industry

At MACH, we specialize in providing advanced CNC tube plasma machines tailored to the needs of the heavy fabrications industry. Designed for robustness, reliability, and ease of use, our machines empower businesses to take control of their tube and pipe cutting operations, delivering unmatched precision and efficiency.

Why Choose MACH CNC Tube Plasma Machines?

1. Precision Built for Heavy Fabrication

Our machines are engineered to handle complex cuts and heavy-duty materials with precision, accommodating everything from mild steel to high-strength alloys.

2. Designed for Tough Jobs

MACH tube plasma systems are built to meet the demands of heavy fabrication industries, cutting through thick-walled pipes and tubes effortlessly and with unparalleled accuracy.

3. Cost-Effective Cutting

By bringing cutting in-house, you’ll save on outsourcing costs while increasing control over your production schedule. With low operational costs and efficient performance, MACH machines are an investment that pays off.

4. Easy to Operate

Our user-friendly interfaces and advanced CNC controls simplify operation, ensuring that both seasoned fabricators and new operators can work with confidence and efficiency.

Key Features of MACH CNC Tube Plasma Machines:

- High-Performance Plasma Sources: Delivering superior cutting power for pipes, tubes, and profiles.

- Durable Machine Frames: Engineered to withstand the rigors of heavy fabrication environments.

- Versatile Cutting Capabilities: Capable of bevel cutting, pipe joint preparation, and more.

- Intelligent Software Integration: Intuitive software for nesting, programming, and real-time monitoring.

- Built-In Safety Systems: Enhanced safety features for operator protection and compliance with industry standards.

Applications:

Our CNC tube plasma machines are ideal for:

- Structural steel fabrication

- Heavy equipment manufacturing

- Industrial piping and ducting

- Custom fabrications requiring precision and durability

MACH Support and Service – We’ve Got You Covered

When you choose MACH, you’re not just getting a machine; you’re gaining a partner in your success.

- Professional Installation & Training: Ensuring you’re ready to hit the ground running.

- Preventative Maintenance Plans: Minimizing downtime and maximizing productivity.

- Responsive Support Team: 24/7 assistance to keep your operations running smoothly.

Let MACH help you take your cutting capabilities to the next level. With our CNC tube plasma machines, you’ll not only achieve superior results but also improve efficiency and profitability in your fabrication processes.

Get in touch today to learn how MACH can power your heavy fabrication projects.

Laser Guided Positioning: Fast Indexing and Reduced Waste

Eliminate scrap, allow full utilization of tube lengths, flip the pipe (end-for-end) or work with pipe longer than

the machine? No problem!

- Dragon will create a mark or etch on the first position of the pipe.

- Release the pipe from the chuck and re-align with a Laser Pointer Light mounted to the head.

- Continue cutting, marking and etching the next position of tubing.