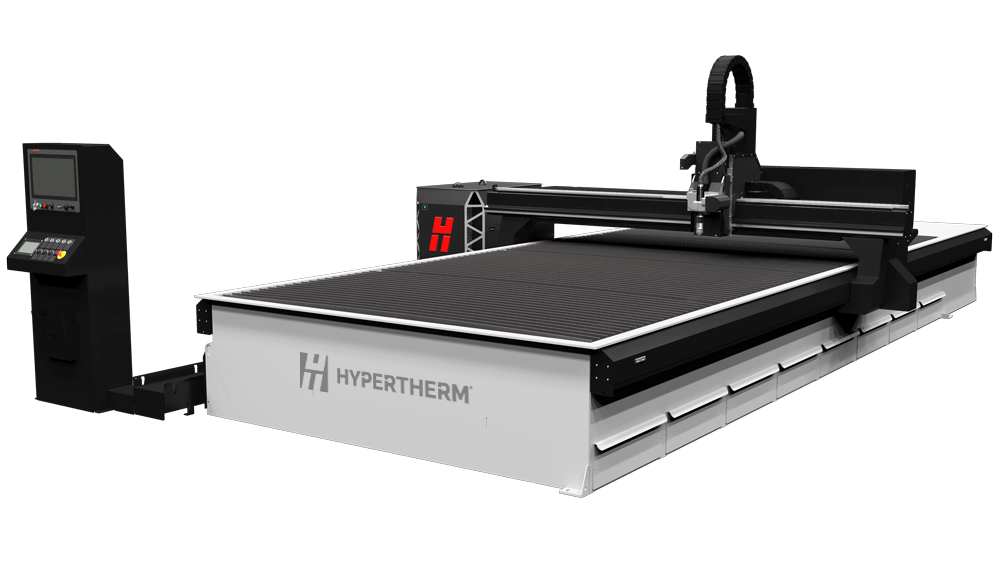

INDUSTRIAL CUTTING SYSTEMS | CNC PLASMA

MACH offers a diverse range of CNC plasma tables to suit any application, from small, compact models perfect for lighter, smaller-scale work to heavy-duty industrial rail CNC plasma systems designed for high-volume, precision cutting on larger materials. Our compact CNC plasma tables are ideal for businesses with limited space or lower production demands, offering exceptional performance and ease of use. For those needing more robust, industrial-grade cutting capabilities, our industrial rail CNC plasma tables are equipped with advanced features, allowing for high-speed, high-precision cuts on large-scale projects. Whatever your production requirements, MACH has the right CNC plasma cutting solution for you.

SPECIFICATIONS

60 Table Sizes

2D and 3D Cutting

European Design

Offline Software

Touch Screen Controls

Partner with MACH?

Knowledge & Innovation

Reliability

Specific Industry Knowledge

Technical Know How

Customer Satisfaction

PLASMA ADVANTAGES

Precision

Accuracy

Support

User Friendly Controls

Reduced Material Waste

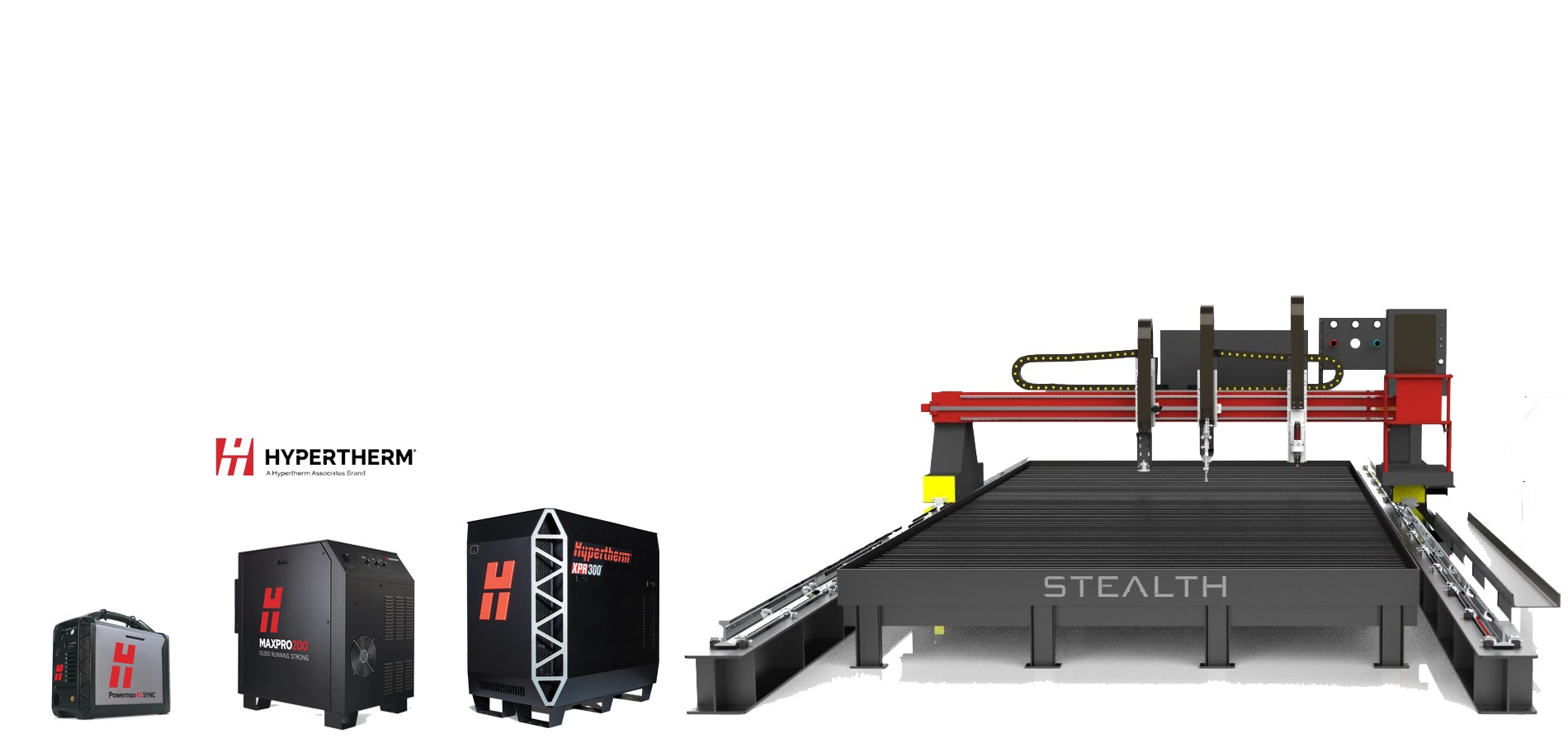

TRUEHOLE PLASMA | HYPERTHERM

Truehole™ technology paired with the new Hypertherm XPR460 offers groundbreaking capabilities in plasma cutting. This advanced system delivers exceptionally round, clean holes with minimal dross, even on thick materials. The XPR460’s precision ensures consistent hole quality, significantly reducing post-processing time and improving overall part accuracy. Truehole™ technology adjusts the plasma arc for optimal cutting conditions, eliminating the need for secondary operations such as drilling or deburring. Ideal for industries requiring high-quality hole perforation, the XPR460 ensures high productivity, reduced material waste, and a seamless cutting experience, providing unparalleled performance in today’s competitive manufacturing landscape.

NEW TORCH TECHNOLOGY

Hypertherm torch technology takes plasma cutting to the next level with enhanced precision and cutting speed. Designed for high-performance and durability, this advanced torch system ensures clean, sharp edges on a wide range of materials. Hypertherm’s innovative technology optimizes arc stability, reducing wear on consumables and extending torch life. With improved heat control and consistent performance, our Hypertherm torches provide superior quality cuts, even on thick materials. This cutting-edge technology minimizes downtime and lowers operating costs, offering businesses a reliable, efficient solution for their most demanding cutting tasks. Upgrade your cutting capabilities with MACH and Hypertherm.

The Versatility of Plasma Cutting

Plasma cutting is one of the most versatile metal cutting solutions available, capable of handling a wide range of materials and thicknesses with ease. From mild steel, stainless steel, and aluminum to more specialized metals like copper and brass, plasma offers unmatched flexibility. Whether you’re cutting thin sheets for intricate designs or thick plates for heavy-duty applications, plasma delivers consistent precision and speed. It’s equally effective for 2D cutting and more complex 3D beveling. Additionally, plasma cutting can be used across industries, from automotive and construction to aerospace and agriculture, making it an indispensable tool for any fabrication shop.

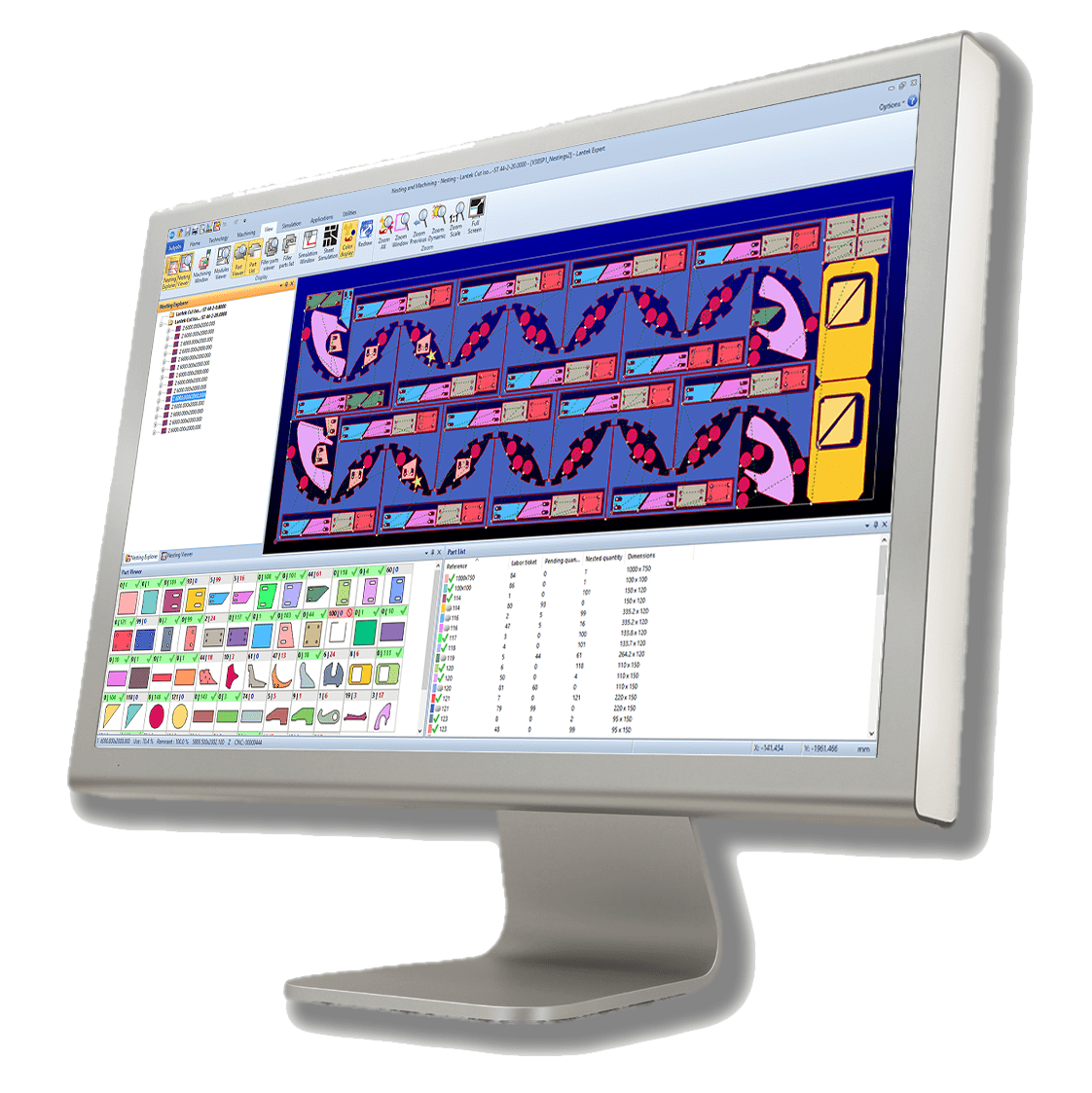

Streamlined Cutting with ProNest® Software

Our CNC plasma systems are powered by ProNest®, Hypertherm’s industry-leading nesting software. Designed to optimize every stage of the cutting process, ProNest® offers advanced features like automatic part nesting, real-time cost tracking, and customizable cut paths. Its intuitive interface seamlessly integrates with CAD systems, simplifying the workflow from design to production. With ProNest®, users can maximize material utilization, reduce waste, and enhance cutting efficiency. The software’s powerful capabilities, including True Hole® and PlateSaver™ technology, ensure precise, high-quality cuts every time. Whether for simple jobs or complex projects, ProNest® empowers businesses to streamline operations and boost profitability

Design to Cut | MADE EASY *

CNC plasma systems streamline the process from design to cutting, making part production faster and more efficient. With user-friendly software, seamless CAD/CAM integration, and intuitive controls, our machines simplify the transition from design files to precise cuts. The advanced nesting features maximize material utilization, while automatic tool height adjustments ensure optimal cutting conditions. Whether you’re creating simple or complex parts, MACH’s systems offer reliable accuracy and high-speed performance, reducing human error and enhancing overall production speed. Our cutting-edge technology makes turning your designs into high-quality finished parts easier than ever before, saving both time and costs.

WE HAVE MORE THAN 30 YEARS OF CNC CUTTING EXPERIENCE

MACH offers CNC Plasma Cutting Machines powered by Hypertherm technology, delivering exceptional power, precision, and efficiency for various industrial applications. Ideal for cutting mild steel, stainless steel, aluminum, and more, our Hypertherm-powered plasma cutting systems offer cost-effective, high-performance solutions for businesses of all sizes. Whether you’re looking to improve your manufacturing process or take on more complex projects, MACH’s CNC plasma machines provide the reliability and precision you need.

Ready to revolutionize your cutting capabilities? Contact MACH today for expert advice and to find the perfect CNC plasma cutting solution for your business!

What You Need to Know Before Buying a CNC Plasma Machine

Before investing in a CNC plasma cutting machine, there are several important factors to consider to ensure you choose the right machine for your needs. Here’s what you should know:

1. Table Size and Cutting Area

The size of the table directly impacts the size of the materials you can cut. Consider your typical material sizes and production volumes when selecting the appropriate table size. Larger tables allow for bigger sheets and better handling of large, heavy materials, whereas smaller tables may be more suited to light fabrication work or compact shop spaces.

2. Motion System

The motion system of your CNC plasma machine will determine the cutting speed and accuracy. Look for machines with a robust motion control system to handle intricate designs and deliver high-speed cuts. A well-engineered motion system ensures smooth, accurate cutting for both simple and complex shapes.

3. Controller and Software

The controller and software play a vital role in the ease of use and functionality of your CNC plasma machine. MACH machines are equipped with intuitive, user-friendly software that allows for quick programming and precise cutting. Make sure the software is compatible with your existing CAD/CAM systems and provides features like automatic nesting, optimized cutting paths, and real-time monitoring for enhanced productivity.

4. Bevel Cutting: 2D vs. 3D

If you need to perform bevel cutting, consider whether a 2D or 3D bevel cutting head is required. 2D bevel cutting is ideal for welding preparations and simple angled cuts, while 3D bevel cutting heads are necessary for more complex geometries and multi-angle cuts. MACH offers advanced 3D bevel cutting solutions to meet even the most demanding fabrication needs.

5. Local Support and Maintenance

It’s crucial to choose a supplier that offers comprehensive local support and maintenance. With Hypertherm-powered machines, MACH provides a dedicated service team for installation, training, preventive maintenance, and troubleshooting. Local service ensures that your machine is kept in top condition for reliable, long-term performance, minimizing downtime and maximizing productivity.

6. Gas Types and Cutting Efficiency

The type of gas you use can significantly impact cutting quality and cost efficiency. Common gases for plasma cutting include oxygen, nitrogen, and compressed air. Oxygen provides faster cutting speeds and better edge quality for mild steel, while nitrogen is ideal for cutting non-ferrous metals like aluminum. Understanding which gas is best for your materials is key to optimizing cutting performance and keeping operational costs under control.

Let MACH Guide You Through Your CNC Plasma Buying Process

Choosing the right CNC plasma cutting machine can seem overwhelming, but MACH is here to help you make an informed decision. Our team will walk you through all the options, ensuring you select a system that fits your unique needs—whether you’re cutting sheet metal, heavy plate, or custom components. Reach out to MACH today and let us provide expert advice, tailored solutions, and reliable support for your business.

Industry Leaders in Supplying Metal Fabrication Machinery

Why Choose MACH?

Industry Leaders

Tailored Solutions

Commitment To Quality & Performance

Trusted By Industry Professionals

Innovative Machinery

Leading Brands and Technologies

Innovative Solutions for Every Need

Proven Track Record of Excellence

Experience/Knowledge

Expertise and Experience

Customer-Centric Approach

Comprehensive Support and Service

Full Tech Support

Proven Track Record

Accessible

Reliable

Industrial Cutting Solutions From Our Range of CNC Plasma Machines

CNC Plasma Cutting with Hypertherm: Power, Precision, and Efficiency

MACH offers CNC Plasma Cutting Machines powered by Hypertherm technology, delivering exceptional power, precision, and efficiency for a wide range of industrial applications. Ideal for cutting mild steel, stainless steel, aluminum, and other metals, our Hypertherm-powered plasma cutting systems are designed to meet the demands of high-performance manufacturing while offering cost-effective solutions for businesses of all sizes.

Why Choose MACH CNC Plasma Cutting with Hypertherm?

1. Hypertherm’s Powerful Cutting Performance

Our CNC plasma systems feature Hypertherm plasma sources, ensuring consistent cutting power and outstanding performance. With high-speed cutting and minimal distortion, Hypertherm plasma delivers clean, precise edges on both thick and thin materials, even on the most challenging jobs.

2. Cost-Effective Solutions with Hypertherm

With Hypertherm’s cutting technology, our CNC plasma cutting machines offer a cost-effective solution to traditional laser cutting. Lower operating costs, faster cutting speeds, and reduced energy consumption make it the ideal choice for businesses looking to improve productivity while managing expenses.

3. User-Friendly Controls with Hypertherm Technology

Our CNC plasma machines equipped with Hypertherm technology come with intuitive, easy-to-use control interfaces. Features like automatic height sensing, real-time monitoring, and Hypertherm’s advanced torch height control ensure optimal cutting conditions and consistent results, reducing human error and improving accuracy.

Key Features of MACH CNC Plasma Machines with Hypertherm:

- Hypertherm Plasma Sources: From 40A to 200A, ensuring efficient cutting for various material thicknesses.

- Precision Motion Control: High-accuracy CNC controls for consistent, clean cuts.

- Heavy-Duty Construction: Built to withstand demanding production environments and large materials.

- Automatic Height Control: Ensures consistent performance with Hypertherm’s advanced torch height control.

- Efficient Fume Extraction: Helps maintain a safe and clean working environment.

Applications:

Our CNC plasma cutting machines powered by Hypertherm are ideal for:

- Metal fabrication

- Automotive manufacturing

- Construction and infrastructure projects

- Sign making

- Custom part production

MACH Support and Service for Hypertherm CNC Plasma

When you invest in MACH’s Hypertherm CNC plasma cutting machines, you’re gaining more than just a machine—you’re gaining a trusted partner. Our expert support team offers:

- Installation & Training: Complete setup and operator training on Hypertherm-powered systems.

- Preventive Maintenance: Keep your Hypertherm CNC plasma cutting machine in top condition for consistent performance.

- 24/7 Service Support: We’re always ready to assist you with your Hypertherm plasma system needs.